In a world where metal reigns supreme, plastic workshop tools are the unsung heroes of DIY projects. They might not have the same intimidating aura as their metal counterparts, but don’t let their lightweight frames fool you. These tools are here to revolutionize your workspace with their versatility and durability. Imagine wielding a drill that won’t rust or a saw that’s as light as a feather—sounds like a dream, right?

But wait, there’s more! Plastic tools are not just about being lightweight; they’re also budget-friendly and easy on the eyes. Who wouldn’t want a pop of color in their toolbox? From crafting masterpieces to tackling home repairs, plastic workshop tools are the secret weapon every DIY enthusiast needs. So, let’s dive into the world of plastic tools and discover why they deserve a spot in every workshop.

Table of Contents

ToggleOverview of Plastic Workshop Tools

Plastic workshop tools offer unique advantages in various DIY projects. They stand out due to their lightweight construction, making them easy to handle during extended use. Many users appreciate their versatility across different tasks, from crafting to household repairs.

Durability is another key feature of plastic tools. These tools resist rust and corrosion, ensuring longevity even under challenging conditions. Different colors and designs enhance aesthetic appeal, adding a vibrant touch to any toolbox.

Budget considerations also favor plastic options. Typically, they cost less than metal counterparts, making them accessible for beginners and seasoned crafters alike. An example includes plastic screwdrivers, which provide adequate performance without the higher expense of metal versions.

Safety plays a crucial role in the appeal of plastic workshop tools. They generally have non-slip grips, reducing accidents during usage. Many users find that this added safety feature is particularly beneficial when working on intricate projects.

Overall, plastic workshop tools combine practicality with affordability, making them essential for anyone looking to enhance their toolkit. From gardening to home improvement tasks, these tools meet various needs while remaining user-friendly. Incorporating plastic tools into a workshop promotes not only efficiency but also creativity in different projects.

Advantages of Using Plastic Workshop Tools

Plastic workshop tools offer numerous advantages for DIY enthusiasts and professionals alike. Their unique properties enhance usability, performance, and safety in various projects.

Lightweight and Portable

Lightweight construction defines plastic workshop tools. Their ease of handling prevents fatigue during extended use. Portability also presents an advantage; transporting tools between projects becomes simple. Users notice the convenience when digging through bags or toolboxes filled with heavier alternatives. Moreover, the energy saved while working allows for greater focus on intricate tasks. Carrying multiple plastic tools for gardening or crafting proves manageable for anyone, enhancing creativity without added strain. Overall, these features make plastic tools a favorite among homeowners and crafters.

Durability and Resistance to Corrosion

Durability characterizes plastic workshop tools. Unlike metal options, these tools resist rust and corrosion. Users appreciate this quality, especially in environments prone to moisture or chemicals. Maintenance reduces significantly due to their resistance, allowing for a longer lifespan. Additionally, plastic can withstand impacts better than some metallic tools. This durability ensures that tools maintain their effectiveness during vigorous applications. The combination of longevity and reliable performance justifies investing in plastic tools for both home repairs and complex projects. Ultimately, these features enhance their practicality in any workshop setting.

Types of Plastic Workshop Tools

Plastic workshop tools come in various types, each designed for specific tasks. Understanding the different categories enhances the selection process for projects.

Hand Tools

Hand tools include screwdrivers, pliers, and wrenches made from durable plastic materials. These tools provide excellent grip and comfort, reducing hand fatigue during extended use. Lightweight designs make these tools easy to maneuver, which benefits both beginners and seasoned crafters. Non-slip features ensure safety during intricate tasks. Additionally, vibrant colors add a fun element to the toolkit, appealing to those who value aesthetics as much as functionality. These hand tools are ideal for home repairs and DIY projects where precision is critical.

Power Tools

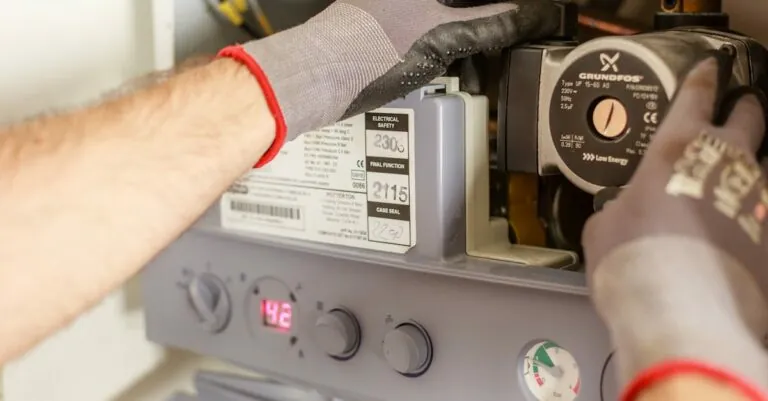

Power tools encompass items like drills, saws, and sanders crafted from high-quality plastic. These tools combine power with safety, making them suitable for various applications. Adequate insulation prevents electrical hazards, ensuring user safety during operation. Lightweight construction allows for easy handling and portability, promoting greater mobility. Versatile designs cater to multiple project types, whether woodworking or crafting. Many models also include features like adjustable speed settings, enhancing control and precision in tasks. Such power tools transform workflows, making them indispensable for any workshop setting.

Best Practices for Maintaining Plastic Workshop Tools

Regular cleaning of plastic workshop tools enhances their performance. Users should utilize mild soap and warm water for routine maintenance. Avoid harsh chemicals that can degrade plastic over time.

Storage solutions play a critical role in prolonging tool life. Keeping tools in a dry, cool area prevents warping and damage. Utilize toolboxes or organizers to avoid clutter and protect tools from impacts.

Inspection of tools helps identify wear and tear early. Regular checks for cracks or loose parts can prevent further damage. Addressing minor issues promptly avoids costly replacements later.

Proper handling techniques contribute significantly to tool longevity. Using tools as intended ensures optimal function and reduces risk of damage. Avoid using excessive force during use, especially on delicate tasks.

Lubrication is vital for moving parts in power tools. Use silicone spray or other plastic-safe lubricants. This process minimizes friction and enhances operational efficiency.

Labeling tools aids in quick identification and streamlines projects. Clearly marked tools reduce time spent searching for items, leading to increased productivity. An organized workspace fosters creativity and efficiency.

Educating oneself on specific materials and uses fortifies appropriate care. Researching the best practices for each tool type ensures users maximize their potential. This understanding leads to better decision-making in tool usage and maintenance.

Following these best practices facilitates the optimal performance of plastic workshop tools. Each measure contributes to extending their lifespan and improving overall effectiveness.

Common Misconceptions About Plastic Workshop Tools

Many people believe that plastic workshop tools lack durability. In reality, modern plastic tools often feature advanced materials that withstand impacts and resist wear. Another misconception is that plastic tools are only suitable for light tasks. They excel in both intricate projects and demanding home repairs, proving their versatility.

Users sometimes think plastic tools are too lightweight to perform effectively. However, their design enhances usability, allowing for greater precision during extended use. Some individuals assume plastic tools offer less safety than metal counterparts. On the contrary, many plastic tools incorporate non-slip grips and insulated handles, minimizing the risk of accidents.

A frequent misconception involves the aesthetic appeal of plastic tools. Colorful designs enhance the visual aspects of any toolbox, allowing for personal expression while working. Cost is another area of misunderstanding. Budget-friendly options often deliver excellent performance, making them accessible for both beginner and experienced DIY enthusiasts.

It’s easy to overlook the maintenance requirements for plastic tools. Regular cleaning with mild soap and warm water keeps them in top condition, while neglecting to maintain them can lead to damage over time. Some believe that all plastic tools weaken over time; however, proper care significantly extends their lifespan.

Eliminating these misconceptions reveals the true value of plastic workshop tools. Their durability, efficiency, safety features, and aesthetic appeal make them an essential choice for a wide range of projects. Understanding these aspects encourages users to incorporate them into their workshops with confidence.

Plastic workshop tools are transforming the way DIY enthusiasts approach their projects. Their lightweight design and vibrant colors not only enhance usability but also make them a stylish addition to any toolbox. With features that prioritize safety and durability, these tools prove to be reliable for both intricate tasks and demanding repairs.

Investing in plastic tools offers a budget-friendly solution without compromising on performance. By understanding their unique advantages and adhering to maintenance best practices, users can maximize the lifespan and effectiveness of their plastic tools. Embracing this innovative category of workshop tools empowers crafters and home repairers alike to tackle projects with confidence and creativity.